Dead stock, also called deadstock, refers to unsold inventory that remains in storage without contributing to revenue. It takes up valuable space, ties up working capital, and often signals inefficiencies in procurement, forecasting, or inventory management.

The consequences of excess inventory extend beyond profit margins. According to the U.S. Environmental Protection Agency (EPA), textile waste alone represented nearly 6% of total municipal solid waste in 2018, reaching an estimated 17 million tons. While not all dead stock is textile-based, these figures illustrate the scale of waste tied to unsold goods and overproduction.

This guide explains the meaning of dead stock, breaks down the most common triggers, and outlines practical steps to reduce and recover from unsold inventory.

What does dead stock mean in business?

In a business context, the term “dead stock” applies to products that are no longer moving through the sales cycle and are unlikely to be sold. Unlike slow-moving stock, which may eventually sell through discounts or seasonal promotions, dead stock typically remains untouched and unmarketable.

This type of inventory strains warehouse resources and limits flexibility. It reduces available space for high-performing items and ties up funds that could otherwise support restocking, product development, or process improvements.

Common causes of dead stock

Dead stock often results from a breakdown in communication between sales, purchasing, and operations. Recognizing the specific causes can help you correct these inefficiencies before they affect profitability.

Inaccurate demand forecasting

When forecasts rely too heavily on assumptions, gut instinct, or outdated data, businesses tend to over-purchase items customers aren’t looking to buy. As a result, these products sit idle, draining resources and cluttering valuable storage space. Inventory forecasting should be based on historical sales trends, market research, and seasonal analysis. Tools allowing demand-driven purchasing decisions can help align stock levels with real-world buying behavior.

Overstocking due to bulk purchasing

While bulk orders can reduce per-unit costs, they often introduce long-term risks if sales volume doesn’t justify the quantity ordered. Inventory acquired to meet volume discounts can quickly become dead stock if demand drops or sales cycles slow unexpectedly. A purchasing strategy that prioritizes flexibility over volume can reduce this risk, especially for new or unproven products.

Seasonal or trend-specific inventory

Products tied to a specific event, season, or trend often have a short shelf life. Failing to sell through inventory within that narrow time frame can lead to sudden overstock. This is especially common in industries like fashion, electronics, and consumer goods. Establish tighter buying windows, more frequent stock evaluations, and exit strategies for unsold inventory to avoid seasonal overages.

Data entry and catalog errors

Seemingly small mistakes in inventory data, such as duplicate stock keeping units (SKUs), incorrect quantities, or mislabeled products, can create confusion across the supply chain. Items may be shelved incorrectly, overlooked in replenishment, or incorrectly flagged as available when they’re not.

Consistent naming conventions and catalog accuracy are essential to maintaining inventory integrity. Implementing a barcode system for your business can significantly reduce entry errors and enhance real-time visibility.

Understanding the importance of inventory accuracy and implementing best practices to maintain it can benefit businesses by allowing them to make better-informed decisions for their operations.

How to identify dead stock in your inventory

Proactively identifying dead stock begins with reviewing detailed sales and inventory reports. Products not sold within a defined period, typically 90, 180, or 365 days, should be flagged for evaluation. When establishing time thresholds, consider product lifecycle expectations and seasonal patterns.

Track the last sold date for each item and compare it to sales velocity. Items that fall significantly below their expected turnover rate may require reclassification or removal from your catalog.

Inventory aging metrics and movement reports are valuable tools in this process. An inventory software solution can simplify this analysis by providing SKU-level data, historical trends, and automated alerts. Platforms designed for real-time inventory monitoring, such as those integrating purchase and sales data, make it easier to identify and act on reducing stagnant stock.

A comprehensive inventory management system like inFlow can also support more effective stock rotation, ordering practices, and decision-making. Additionally, signing up for StockTrim enables data‑driven purchasing decisions, preventing dead stock by aligning orders with real demand.

Hidden costs of dead stock

The financial burden of dead stock extends beyond the cost of unsold products. Businesses absorb ongoing storage expenses, potential write-offs, and additional labor to manage excess inventory. These losses often compound over time, eroding profit margins and operational efficiency.

There is also an opportunity cost involved. Capital tied up in non-performing items is unavailable for purchasing in-demand products or investing in growth initiatives. The longer dead stock remains on shelves, the more it hinders business agility.

Operationally, excess inventory clutters the warehouse and complicates pick-and-pack workflows. As a result, employee productivity decreases, and order accuracy may decline. Leveraging a warehouse management software system can help streamline operations, improve visibility, and optimize space allocation for faster-moving items.

Solutions to reduce and prevent dead stock

While dead stock can disrupt inventory flow and chip away at profit margins, it’s also preventable. Implementing the right strategies at operational and planning levels allows you to avoid unnecessary buildup and respond more effectively when overstock occurs.

Here are practical solutions to help you reduce and prevent dead stock:

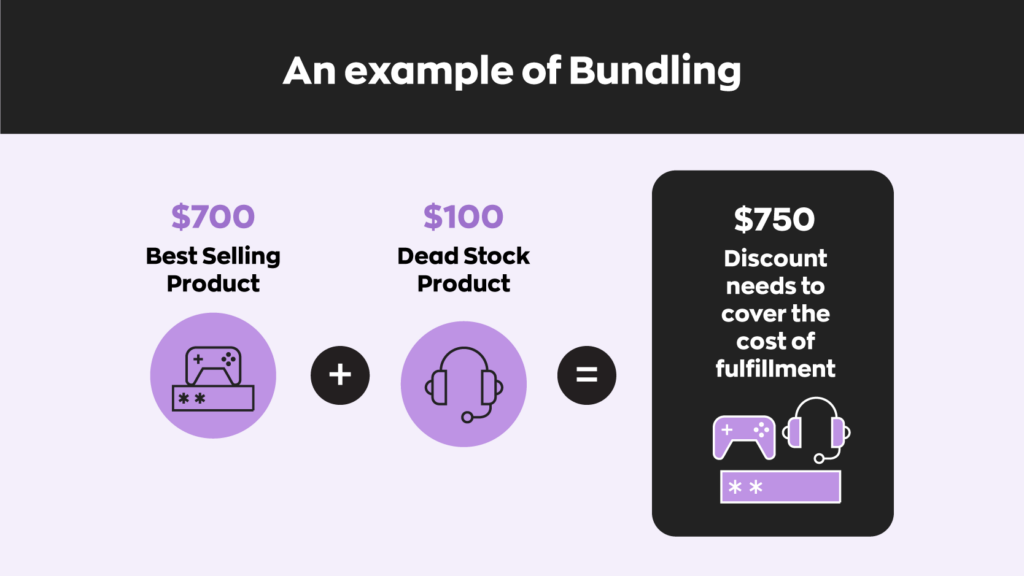

- Bundle slower-moving products with popular items: Create value packs or bundles that pair stagnant inventory with top-selling SKUs. This increases visibility and appeal, helping you move more inventory without deep discounts.

- Use flash sales or clearance campaigns strategically: Launch limited-time promotions to offload aging stock quickly. Flash sales are especially useful for seasonal items or goods nearing obsolescence.

- Invest in forecasting and purchasing software: A purchasing system directly connected to real-time demand can reduce overordering. Tools that support production planning and demand forecasting, such as inventory platforms built for manufacturing operations, help your team make informed decisions.

- Improve order accuracy to reduce returns: Returns often lead to items being reclassified as dead stock, especially if packaging is damaged or restocking is delayed. Tools that handle sales and invoicing efficiently help reduce shipping errors and ensure fulfillment matches expectations.

- Train staff on inventory protocols: Even the best systems can’t perform if teams don’t use them correctly. Provide ongoing training to ensure accurate data entry, proper receiving procedures, and routine stock audits.

Implementing these inventory management best practices can significantly benefit your business, leading to increased efficiency, reduced costs, and improved customer satisfaction.

0 Comments