Key takeaways

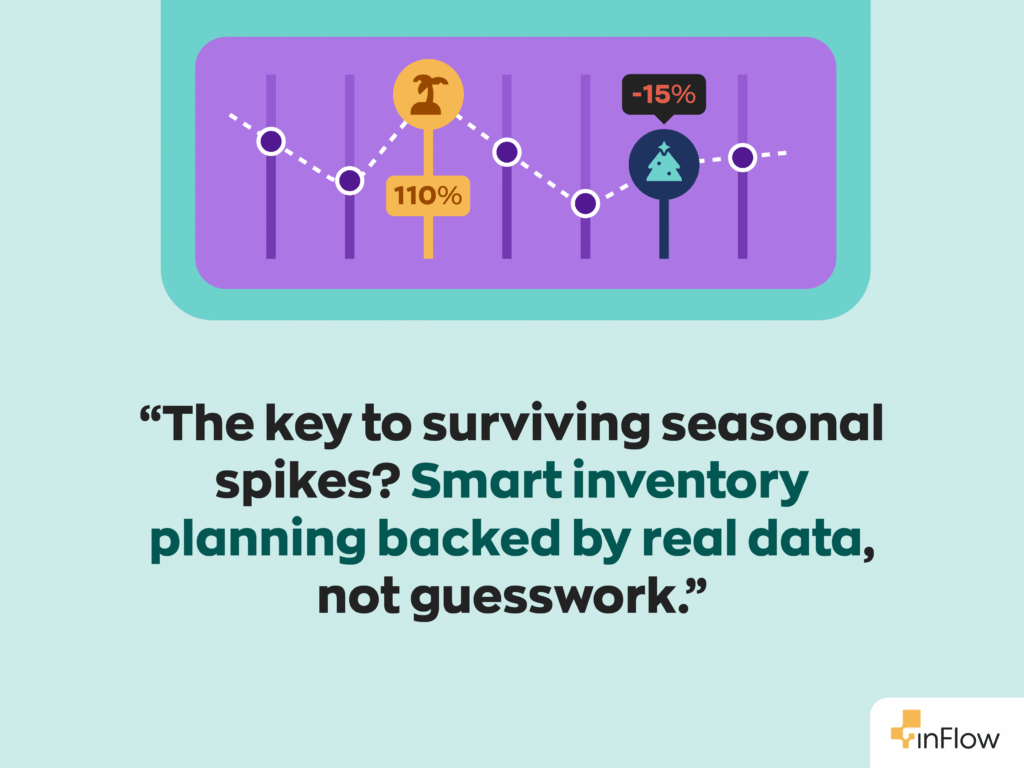

- Seasonal inventory planning relies on finding the right balance by combining historical data with real-time insights to stay ahead of demand.

- Forecast more effectively by reviewing past sales, tracking market trends, and adapting to local events like bank holidays or school breaks.

- Prevent both stockouts and excess inventory by setting accurate reorder points, adjusting safety stock, and planning around supplier lead times.

- Strengthen your supplier relationships and build a diverse network to stay flexible and reduce fulfilment risks during busy periods.

- Use creative strategies to manage deadstock, such as bundling, off-season promotions, or expanding to new sales channels.

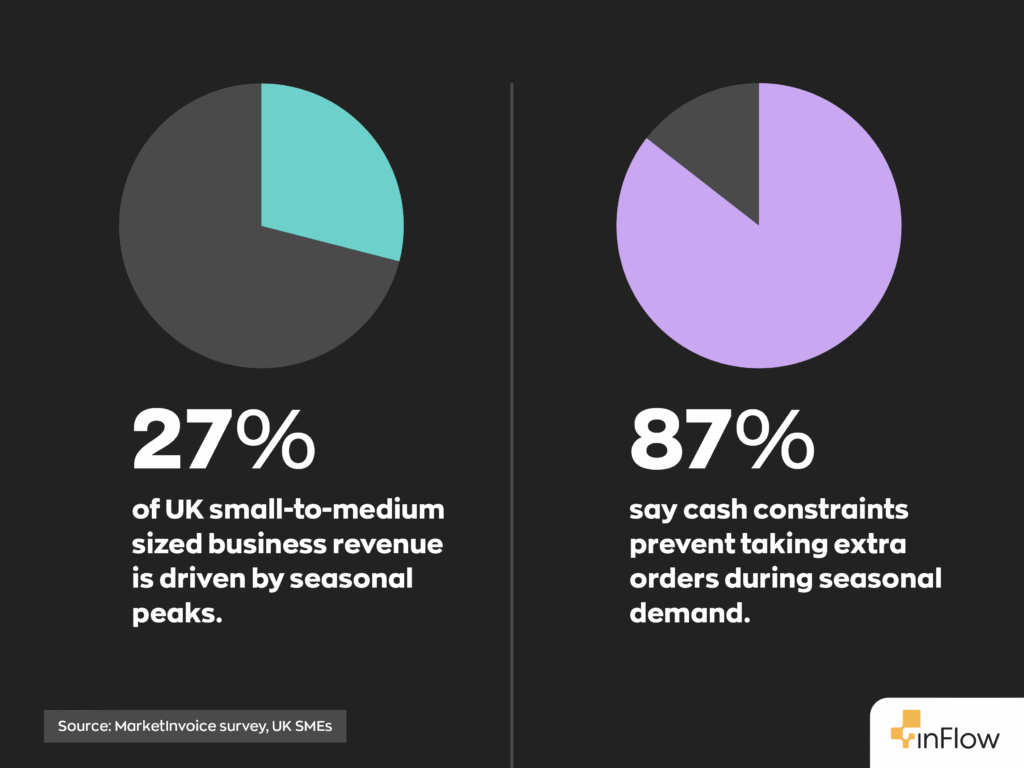

Seasonal peaks like Christmas, Black Friday, and summer sales represent some of the best opportunities for small businesses, but they come with their fair share of challenges too. You might see an influx of customers and sales, but without well-orchestrated inventory planning, these busy periods can lead to excess inventory, missed orders, or dissatisfied customers. The key is balance: blend data-driven decisions with practical strategies, lean on technology, and remain agile to better weather changing conditions.

Here’s a step-by-step guide to help small and medium businesses build resilient, smarter inventory plans for whatever the season brings.

Forecasting demand: Unpacking the data and reading the signals

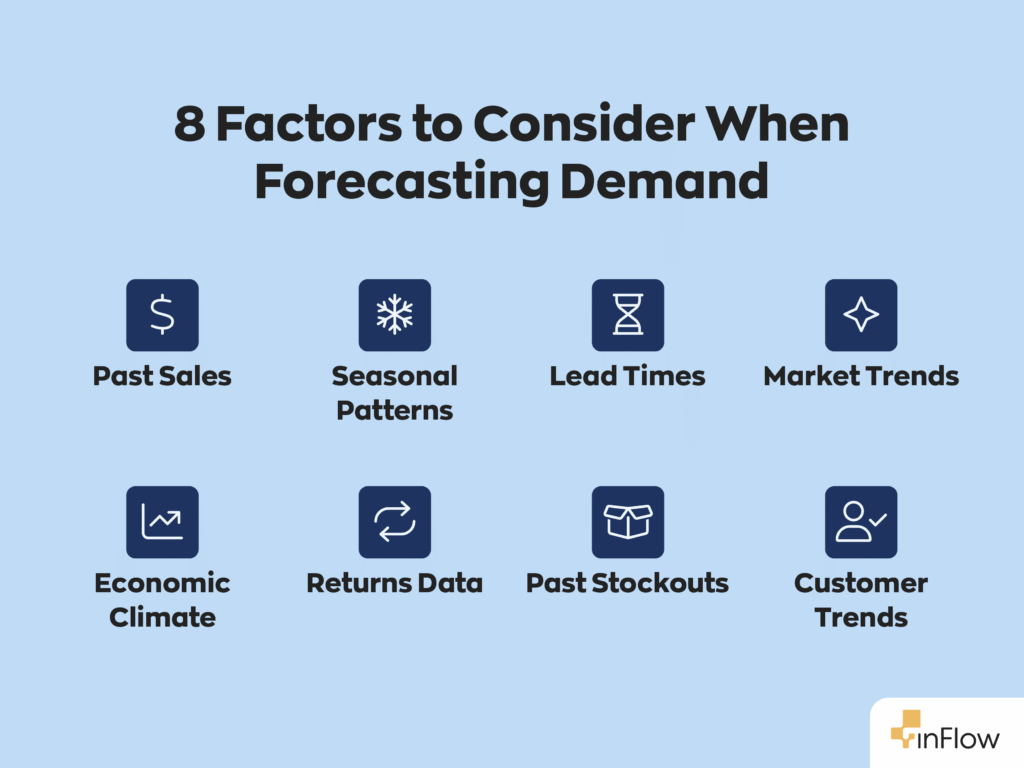

Strong inventory planning always starts with understanding your demand. Begin by reviewing your historical sales data for previous peak seasons. Are there products that consistently outperform others during Christmas, or do some surprise you with sudden popularity during summer events? Take into account local influences like school breaks, bank holidays, big football matches, or changes in weather because these can all shift buying habits.

But it’s not all about looking backward. Consider broader market research, too: pay attention to nationwide retail trends, scan competitor activity, and keep an eye on regional news that could impact customer behaviour. Combining your own data with these wider industry signals – and enhancing it with predictive analytics or sales forecasting tools – can give you a much more accurate picture of what’s coming, so you can stock the right items at the right times.

And this is just the beginning. There are actually seven distinct types of demand forecasting, each suited to different goals and business models. Choosing the right one can give you a sharper edge – whether you’re aiming to minimise stockouts, optimise your storage, or simply forecast more confidently during seasonal surges.

It’s also worth carving out time at the end of each busy season to review what worked (and what didn’t). These post-mortems aren’t just good for refining future plans; they also help foster a mindset of continuous improvement across your team.

Prevent stockouts and overstocks

Once you’ve got a grip on likely demand, it’s time to get strategic about your inventory planning. This means thinking beyond just having enough. Instead, aim for the right amount, at the right time, in the right place. To avoid stockouts and overstocks, it’s essential to follow the right steps:

- Set clear reorder points: Calculate when each key product needs restocking based on both past sales and forecasted upswings. With inFlow, you can calculate reorder points for each of your products. When your stock dips below a reorder point, you’ll be notified immediately.

- Adjust safety stock levels: It’s always a good idea to keep a certain amount of safety stock available. For seasonal inventory, it’s best to adjust safety stock levels to reflect volatility (like unpredictable spikes during holiday periods).

- Account for supplier variability: Build in extra padding for items sourced from suppliers with longer lead times or a history of delays. For UK businesses dependent on international shipping, this is especially important during peak customs periods.

- Segment your stock: Some products fly off the shelves during promotions, while others move more slowly. Identifying your ‘fast movers’ and ‘slow movers’ lets you refine how you allocate storage space and capital.

Having these strategies in place helps minimise risk. You won’t have cash tied up in excess inventory, and you won’t leave loyal customers disappointed by empty shelves either.

Build flexibility and foster relationships

Procurement goes beyond simply placing orders. It’s about staying agile in the face of shifting demand. Building strong relationships with your suppliers and maintaining open communication around your forecasts can make a real difference in your inventory planning. When your partners understand your plans, they’re more likely to offer flexibility, priority support, or faster turnarounds when you need them most. Consider the following:

- Diversify your suppliers: Don’t put all your eggs in one basket. Relying on one supplier might simplify things, but it also creates risk. If they face delays or stock issues, your whole supply chain can be disrupted. By building relationships with multiple vendors, you gain flexibility and a safety net.

- Stay agile in fulfilment: Ramp up your order fulfilment processes ahead of busy periods. Consider cross-training staff or bringing in seasonal help so you can scale quickly. Using an omnichannel approach (where your store, website, and any third-party marketplaces are all drawing from the same inventory) helps keep stock levels visible and accurate.

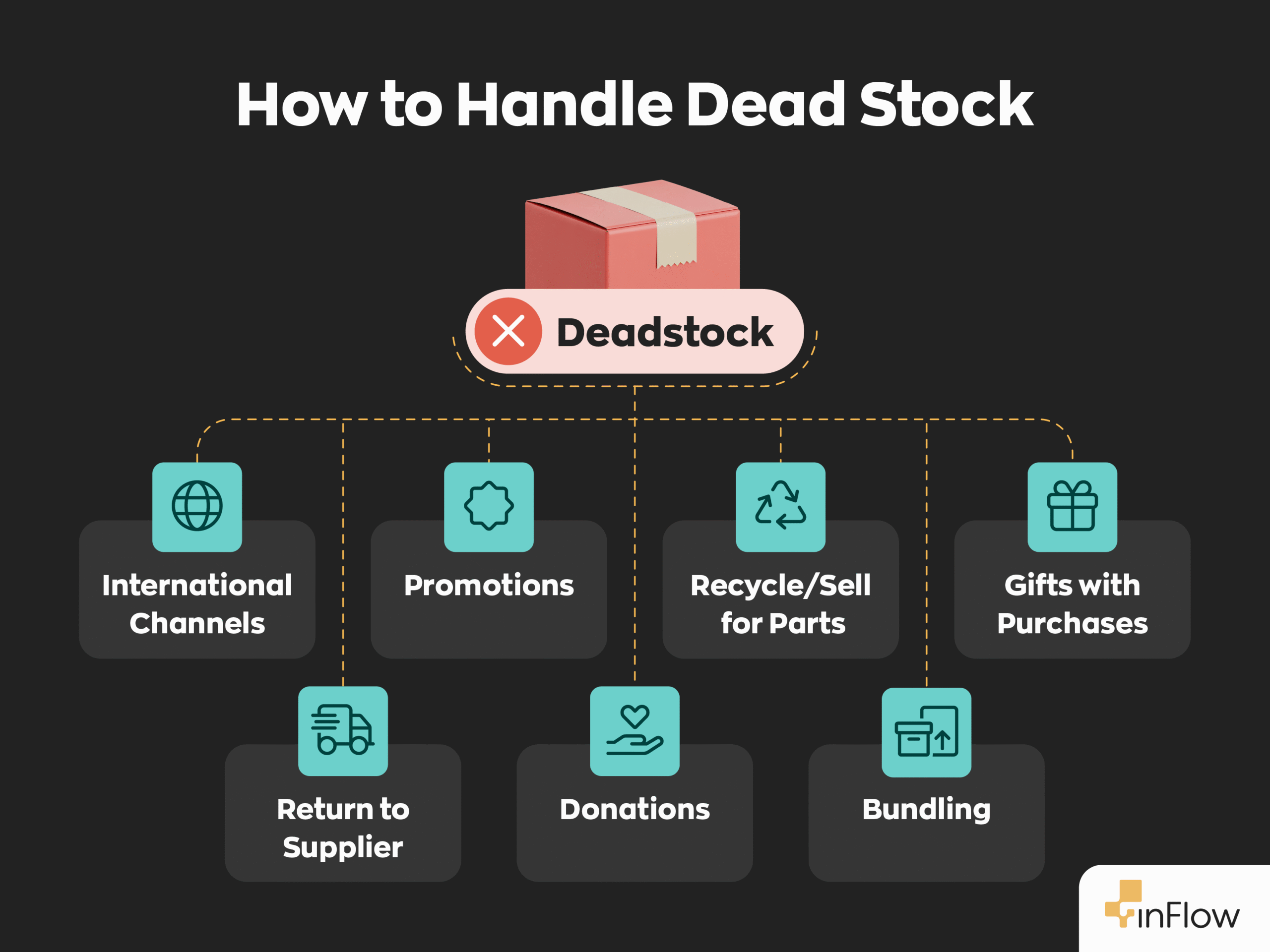

Get creative with deadstock

Even the best forecasts aren’t foolproof. Sometimes, you’ll end up with more stock than you intended. Instead of viewing this as a setback, treat your deadstock as an opportunity to get creative:

- Offer off-season promotions: Use targeted email campaigns or limited-time offers to move slow sellers. It’s a great way to drive traffic during quieter periods and re-engage past customers.

- Bundle products: Pair overstocked items with high-demand products. This not only boosts average order value but also helps move less popular stock more quickly.

- Expand sales channels: If you’re sitting on UK-specific surplus, explore listing on international platforms (especially if you’ve already got global shipping capabilities in place). What’s in surplus locally might be in high demand elsewhere.

Approaching overstock with this mindset helps preserve cash flow, reduces holding costs, and keeps your inventory fresh – all while providing added value to your customers.

Leverage the best tech

Modern inventory management software, like inFlow, streamlines every step of seasonal inventory planning – helping you stay ahead of demand, reduce errors, and save valuable time. With the right system in place, you’ll benefit from:

- Real-time visibility: inFlow’s barcodes and cloud-based tools provide real-time stock visibility. Instantly see what’s in stock, what’s moving quickly, and where you’re running low across all channels and locations.

- Automated reorder points: As mentioned earlier, setting up automated reorder points can be a game-changer during seasonal peaks. With inFlow, you’ll receive timely alerts when stock levels drop, helping you restock in time and avoid late orders or missed sales.

- Data-driven insights: With inFlow, you can generate customisable reports that highlight sales trends, flag your top-performing products, and track inventory movement over time. These insights help you plan for seasonal peaks with greater confidence and ensure your stock levels align with actual demand rather than relying on gut instinct.

Final thoughts

Seasonal inventory planning doesn’t need to be a guessing game. With the right mix of forecasting, flexible procurement, smart stock strategies, and reliable technology, small businesses can turn seasonal challenges into growth opportunities.

inFlow helps you stay one step ahead by giving you the tools to predict demand, optimise stock levels, streamline fulfilment, and make data-backed decisions at every turn. The result? Fewer stockouts, less deadstock, and a smoother path to customer satisfaction.

0 Comments