Key takeaways

- The UK still faces an ongoing HGV driver shortage. They’ll need around 40,000 new drivers annually over the next five years to keep supply chains moving.

- The shortage peaked in 2021 and continues to disrupt SMBs, especially those without the resources of larger businesses.

- Small and medium businesses are more vulnerable to delays, rising costs, and stock shortages. Particularly if they rely on just-in-time inventory models.

- To minimise disruption, SMBs should focus on building more resilient supply chain strategies. They can do this by diversifying delivery partners, working with local suppliers, and holding strategic buffer stock.

- Adopting an inventory management system like inFlow can help SMBs stay proactive with real-time tracking, automated reordering, demand forecasting, and streamlined operations.

You’ve probably heard about the lorry driver shortage in the UK. And if you own a small or medium business, you’ve likely felt its impact too. From late deliveries and production hold-ups to stock shortages and increased operational costs, the HGV driver shortage has caused a ton of disruption. To make matters worse, the shortage disproportionately hits small and medium businesses hardest.

In this article, we’ll explain exactly what the HGV driver shortage is, which industries are affected, and what you can do to minimise its disruption to your business.

What is the HGV driver shortage?

The HGV driver shortage refers to the significant lack of qualified Heavy Goods Vehicle (or ‘HGV’ for short) drivers across the UK. There simply aren’t enough lorry drivers to operate the number of large freight vehicles needed to keep our shelves stocked and the wheels of the British economy rolling.

According to a recent report by the Road Haulage Association (RHA), we’ll need to see some 40,000 new lorry drivers recruited annually over the next five years in order to meet future demand and growth. However, in order to reach that target, the government will need to invest mainly in HGV training programs and retention incentives. They’ll also need to find ways to make the profession more attractive to young people. According to data from the Office of National Statistics (ONS), less than 2% of HGV drivers are under 25. At the same time, the RHA report shows that the average age of lorry drivers is 51, and that 55% of lorry drivers are between 50 and 65. This means that most experienced HGV drivers will be retiring over the next decade while the onboarding of young recruits continues to crawl along.

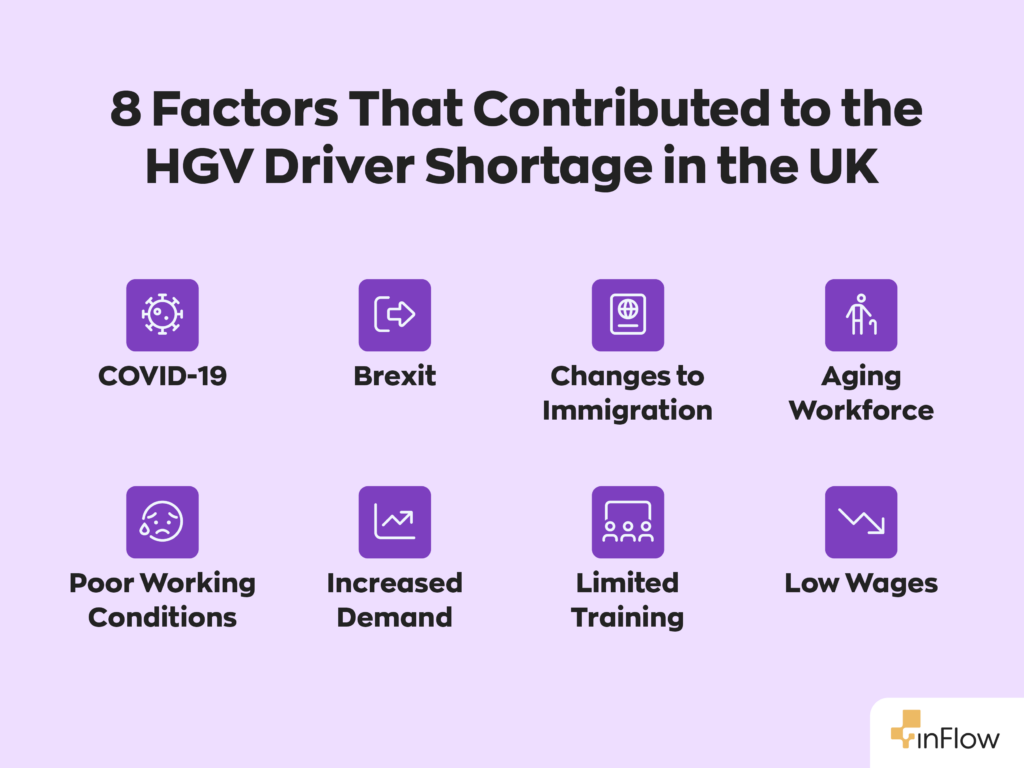

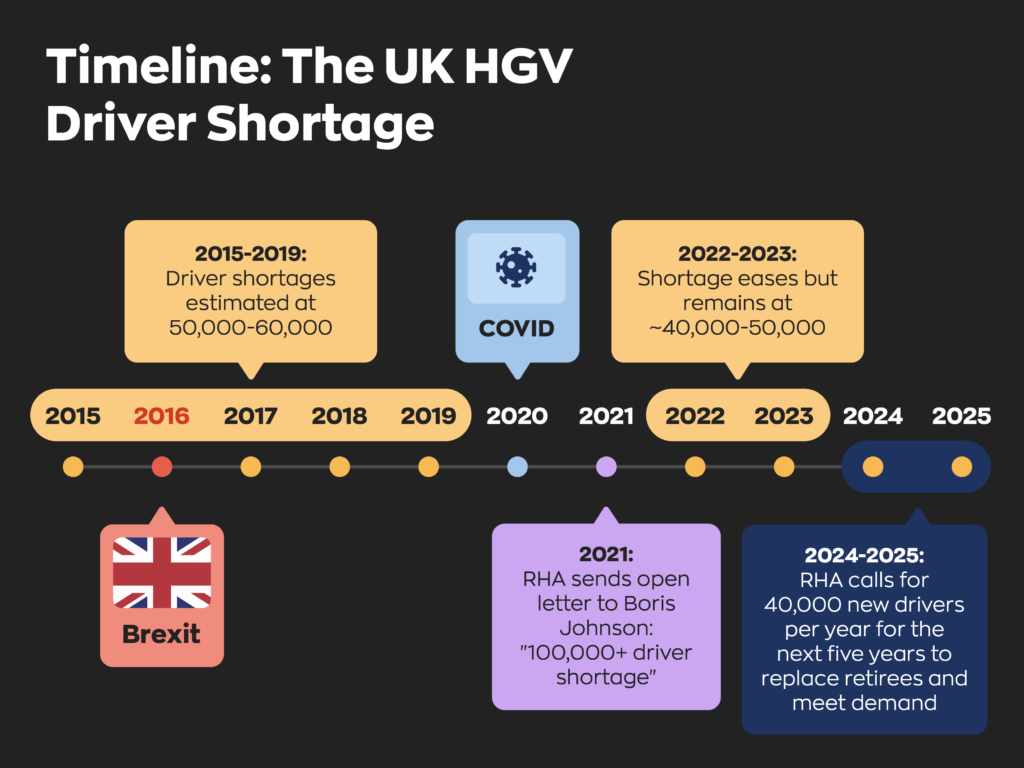

What caused the HGV driver shortage?

The shortage isn’t a new problem. In fact, it’s been bubbling under the surface for the past decade or so. Back in 2018, the UK was short of HGV drivers by about 52,000 (FTA). However, the crisis hit its true peak in 2021 when a combination of Brexit backlash and Covid restrictions saw this number skyrocket to more than 100,000. British withdrawal from the European Union resulted in the loss of some 16,000 EU drivers, which, in combination with 25,000 fewer HGV test passes due to COVID-19 disruptions, culminated in the whopping shortage (UK Parliament).

While the situation has certainly improved and somewhat stabilised since 2021, the driver shortage and subsequent disruption to UK supply chains continue full steam ahead. The profession’s low entry rate is largely considered a reflection of the industry’s negative reputation. Long working hours, low pay, extended periods away from home, poor working conditions, and ill-equipped roadside facilities are often cited as the biggest turn-offs. While the government has introduced several measures to combat the issue, there’s still a fair bit of work to be done.

How does the shortage disrupt supply chains?

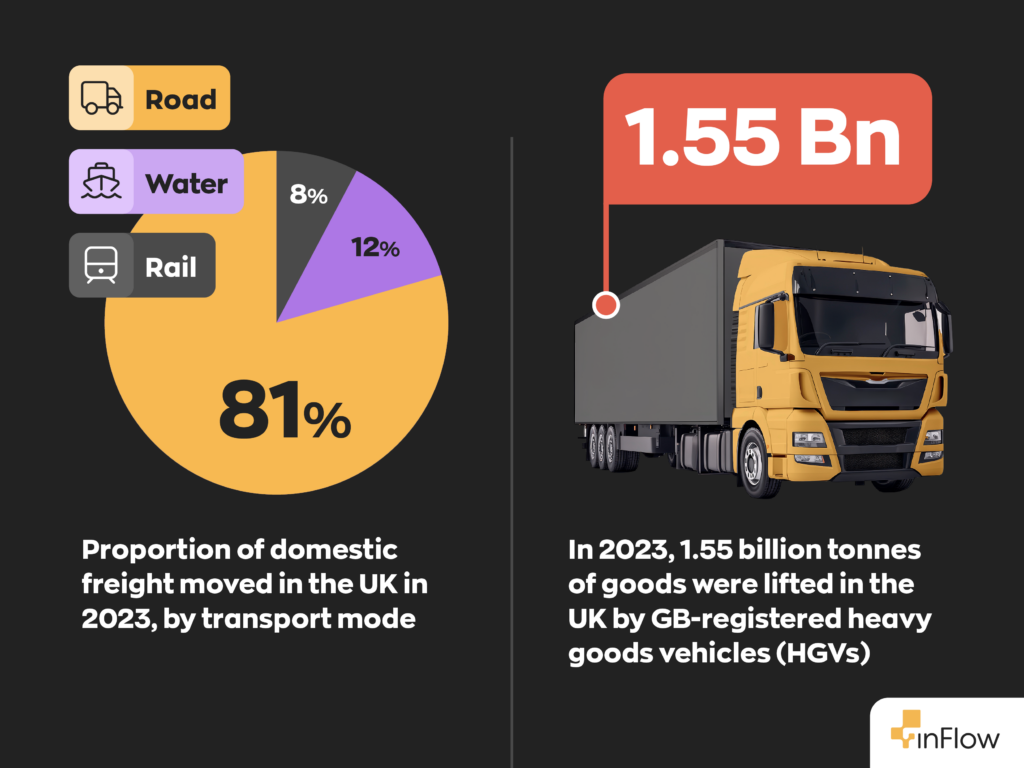

There’s no doubt we’re short on lorry drivers, but the list of problems this crisis causes is anything but short. Like all economies, the UK relies on transport and logistics to produce, store inventory, deliver, and distribute goods and services. According to recent data from the Department for Transport (DfT), road freight accounts for 81% of all domestic freight transport in the UK, while waterways account for 12% and rail just 8%. So, it’s clear to see how a shortage of lorry drivers can throw a massive spanner in the works.

And, unfortunately, small and medium businesses bear the brunt of the HGV driver shortage. While larger companies will feel an impact, they’re better equipped to weather the storm. This is because they can pay a premium to secure transport (which most SMBs simply can’t afford). And when fewer drivers are available to deliver goods, the logistics networks that keep small and medium businesses running slow down. SMBs face late deliveries, manufacturers awaiting materials face production hold-ups, and businesses reliant on just-in-time supply chains are first on the chopping block.

We saw the full effect of the shortage in 2021 when customers were met with empty shelves. Retailers lost out on crucial sales during peak trading periods like Christmas and the back-to-school season. Haulage companies also took a hit, having to fork out higher wages to attract and keep drivers. Not to mention, the farmers had no other choice but to leave produce rotting in fields because they couldn’t secure the transportation needed to deliver their goods.

For small and medium businesses today, the shortage continues to cause a major supply chain bottleneck. The result is constant uncertainty: juggling late shipments, unpredictable stock levels, and rising costs. Because of this, many businesses find themselves managing their stock more reactively. The trouble with this is that it can lead to over-ordering, understocking, or missed opportunities. Unlike larger companies with dedicated logistics teams and access to all sorts of resources, SMBs need smarter systems and better planning tools to keep up.

What can you do about the HGV driver shortage?

Let’s be honest, there’s not much you can do about the lorry driver shortage – at least not directly. But there are a number of measures you can implement to ease its impact. The key is to build a robust supply chain strategy that can withstand a few knocks.

Shift from reactive to proactive stock management

SMBs tend to get stuck in a reactive mindset regarding stock control. Often, they only take charge and make changes in response to external factors. With small teams and over-stretched resources, it’s easy to understand why many fall into this trap. But by adjusting your mindset – and adopting the right tools – you can prevent stockouts, over-ordering, and last-minute scrambles. Inventory management tools like inFlow can help by offering real-time tracking, automated reordering, and accurate demand forecasting to give you more control over your stock.

Diversify & localise your supply chain

Relying on a single logistics partner is risky considering the HGV driver shortage and how tight it’s making driver availability. We advise that you don’t put all your eggs in one basket. Instead, opt for a multi-delivery provider solution to maximize flexibility if things go haywire. You might also consider working with local or regional suppliers to reduce your reliance on long-haul transport. Essentially, the closer your sources are and the more diverse your transport options are, the better.

Build a strategic buffer

In times of crisis, businesses tend to fall into one of two categories: the panic over-stocker or the ultra-lean under-stocker. While having a lean inventory model is great for minimising waste, reducing holding costs, and improving efficiency, it can cause serious problems during supply chain disruption. To counter this, we recommend holding buffer stock of essential or high-turnover items to help bridge delivery gaps and ensure supply continuity.

Streamline internal operations

To have things run as smoothly as possible, you’ll want to have all your internal operations in one place. This will help you get a clear bird’s eye view of your business and save you a lot of time by reducing manual errors. With inFlow, you can automate purchase orders, track stock movements in real time, and centralise communications with suppliers all in one system. We also have handy features like built-in barcode scanning, mobile access, and custom workflows that you can tailor to your exact needs.

Keep customers in the loop

There’s no denying that delays can be a real pain, but SMBs can ease the burden by keeping the lines of communication open. This will help maintain customer trust and maintain brand reputation even when shipments slow down. With inFlow, you can check fulfilment progress, generate invoices or packing slips instantly, and even respond directly to customer queries.

Be flexible & stay informed

This ties back to the earlier point about being proactive rather than reactive. If you can monitor trends and stay informed, it’ll help you prepare and navigate potential supply chain disruptions. We’ve got tools that can make this easier. inFlow’s reporting dashboards and real-time analytics can help you monitor stock movement, lead times, and supplier performance. The goal is to help you make faster (and more accurate) decisions.

Wrapping up

The HGV driver shortage isn’t going away overnight, but that doesn’t mean your business has to suffer. For small and medium businesses, the key is taking control of what you can manage. Things like your inventory, operations, and customer relationships. By shifting from reactive stock management to a more proactive, data-driven approach, you’ll be better prepared to weather the unpredictable supply chain management storm.

Tools like inFlow can make all the difference. From real-time inventory tracking to smart reorder alerts and streamlined internal workflows, inFlow gives you the visibility and control you need to stay one step ahead (even when driver numbers are down, and delivery timelines are up in the air). The UK’s logistics challenges may be complex, but that doesn’t mean your business has to get stuck in traffic.

0 Comments